Across many markets, project owners and contractors are re-evaluating how they build concrete structures. Labour shortages, rising material prices, and higher expectations for finishing quality have pushed developers to look closer at construction methods that offer both speed and precision. One solution receiving consistent attention is the aluminium formwork system.

Years ago, timber and steel dominated building sites. Today, however, developers who pursue stable schedules and predictable quality increasingly choose aluminium formwork for housing projects, high-rise buildings, hotels, and other cast-in-place concrete structures. The shift didn’t happen overnight—it’s driven by practical jobsite needs.

Speed: The First Reason Developers Take a Closer Look

One of the strongest motivations behind the move to aluminium formwork is its predictable cycle time. Once a team becomes familiar with the system, it’s common to complete the pouring of one floor in three to five days.

Contractors often share the same observation: aluminium panels are light, easy to handle, and allow teams to finish reinforcement, installation, pouring, and stripping with far less waiting time. This speed gives developers a clearer timeline when planning sales launches, financing milestones, and labor allocation.

Shorter cycles also support stable cash flow. Projects can advance with fewer delays, and the reduced reliance on heavy lifting equipment helps prevent bottlenecks from crane scheduling.

Aluminium Formwork System

Cleaner Finishing Without Rework

A major complaint with traditional formwork is the amount of rework required after stripping. Uneven surfaces, honeycombing, and alignment issues lead to more plastering, more material consumption, and more labour cost.

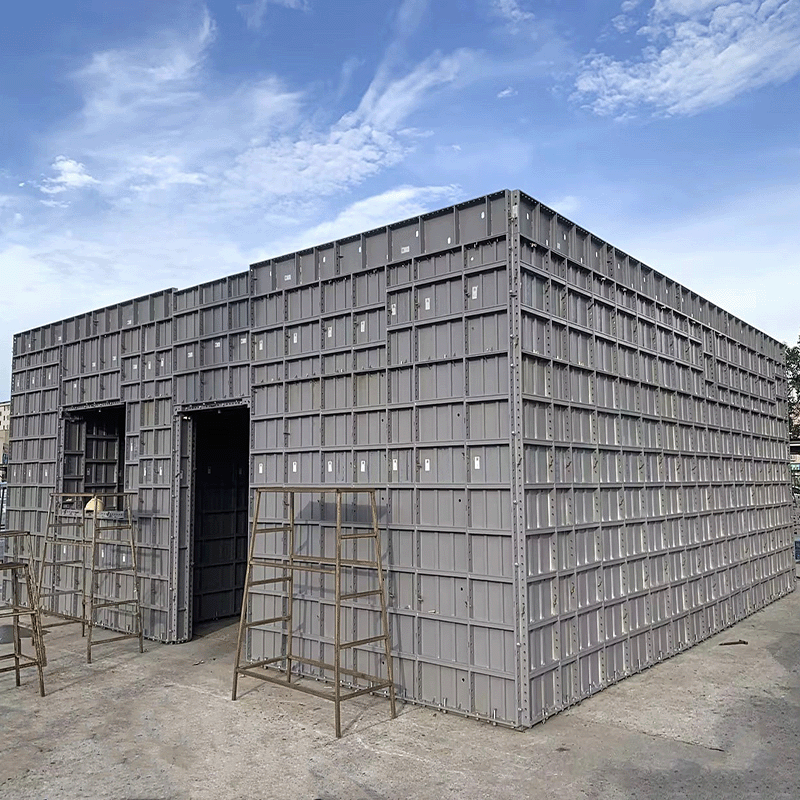

An aluminium formwork system provides superior control over concrete quality. Its precisely manufactured panels and tight joints ensure excellent verticality and surface flatness. Developers appreciate that this level of accuracy removes the need for plaster, reduces finishing layers, and minimises cracks caused by thick mortar applications.

In large residential projects, this difference is not minor—it can save weeks of additional labour and a significant portion of the finishing budget.

A Solution That Fits Many Project Types

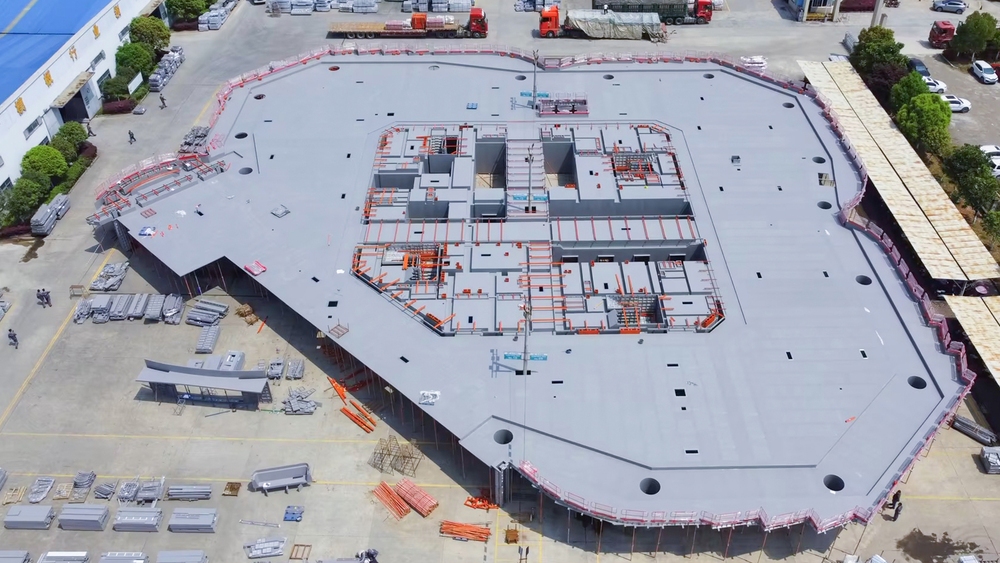

Aluminium formwork systems are highly versatile, making them suitable for a wide variety of cast-in-place concrete projects. From residential and commercial buildings to infrastructure projects, the system can adapt to different structural layouts, wall thicknesses, and floor plans.

- In residential construction, aluminium formwork helps achieve uniform quality across multiple units, ensuring walls, columns, and slabs are consistently flat and vertical.

- In commercial or office buildings, it supports faster floor-to-floor cycles, reducing the overall construction timeline.

- Industrial structures and civil works, such as utility facilities or underground concrete components, benefit from the system’s modularity and ease of assembly, which can accommodate irregular shapes and complex geometries.

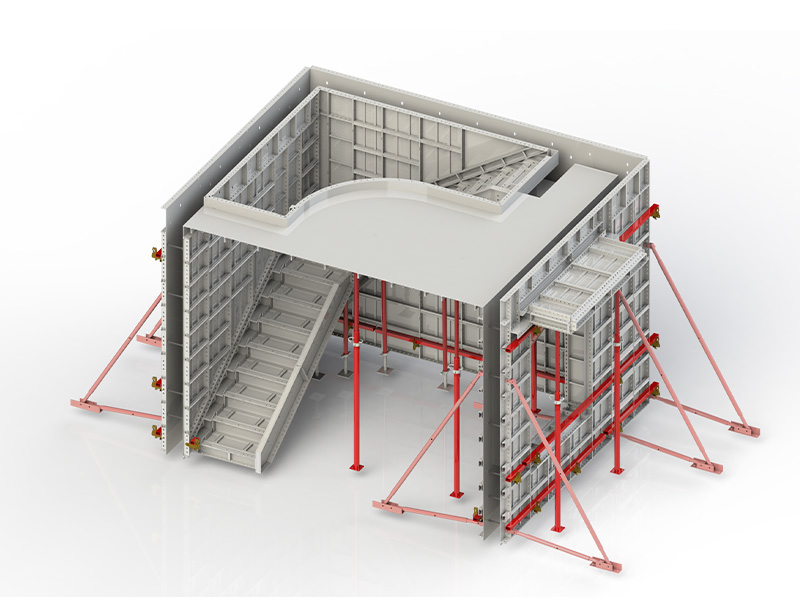

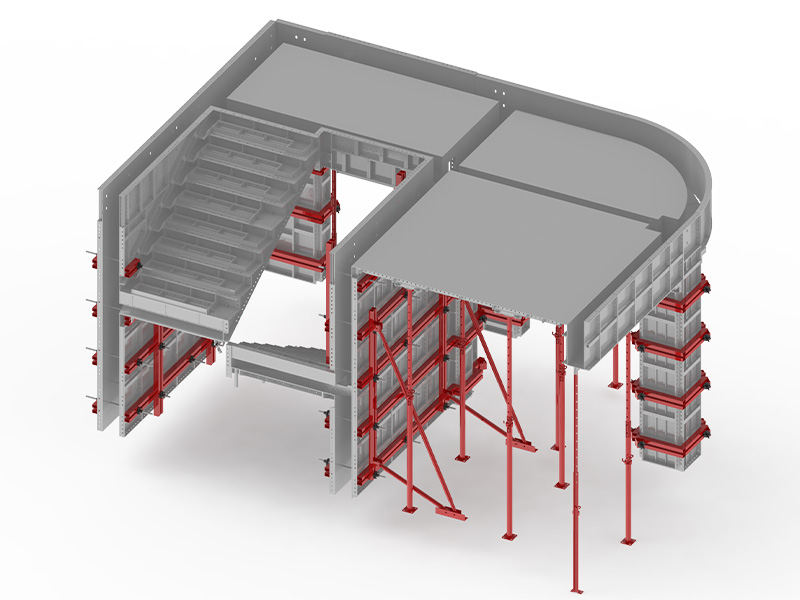

The flexibility of aluminium formwork also allows contractors to combine panels to suit different structural needs. This adaptability means that one formwork system can cover multiple types of concrete elements, including walls, beams, columns, slabs, and staircases, without requiring entirely new setups for each variation. For developers and project managers, this translates into smoother planning, predictable timelines, and more reliable quality control across diverse project types.

Aluminium Formwork Installation for Villas

Lower Long-Term Costs Through Reuse

At first glance, some developers assume aluminium formwork is more expensive than timber. But once the project is underway, the cost difference often shifts in aluminium’s favour.

The high reuse rate plays a key role. A well-maintained set can be used across many floors, blocks, or even multiple projects. When combined with the reduced need for plastering, lower labour requirements, and minimal equipment leasing, the integrated cost becomes far more competitive than traditional methods.

The scrap value of aluminium also strengthens the final return, reducing the net cost of ownership.

Improved Jobsite Safety and Stability

Developers place increasing importance on site safety, and formwork systems are a big part of that discussion. Aluminium formwork is made from high-strength aluminium alloy profiles that go through machining, welding, and strict production processes.

Once connected, the system forms a stable frame with strong bearing capacity and resistance to deformation. Workers handle lighter panels, which lowers the risk of handling injuries compared to heavier steel or bulky timber boards. Reduced drilling, especially when using flat-tie systems, also means cleaner workspaces and fewer hazards.

Options That Match Different Construction Habits

On construction sites across different countries, teams often follow their own working habits based on experience, project type, and local standards. Modern aluminium formwork systems can adapt to these differences, which is one of the reasons they are accepted so widely.

Some contractors prefer a reinforcement approach that minimises drilling and accessory handling, while others choose a setup that offers stronger bracing for thick walls or irregular layouts. Aluminium formwork manufacturers typically provide several reinforcement methods to match these preferences.

This flexibility allows contractors to continue using familiar workflows while upgrading to a more efficient building method. For developers, this means a smoother learning curve for workers and fewer adjustments on site.

Aluminium Formwork System

GETO Aluminium Formwork System

Before contractors commit to an aluminium formwork supplier, they usually look closely at consistency, engineering capability, and how well the system supports their project type. GETO has positioned its aluminium formwork system as a practical solution for developers who want stable cycle times and predictable casting quality without complicating site operations.

Designed Around Real Project Needs

The GETO aluminium formwork system is developed to support cast-in-place concrete structures in residential buildings, villas, commercial projects, and different forms of urban infrastructure. Instead of providing a single rigid setup, the system is engineered so that panels, connectors and reinforcement approaches can be arranged to fit different structural layouts. This adaptability helps contractors maintain a fast installation rhythm, even on projects where unit types or wall thicknesses vary.

Formwork Reinforcement Options

To match different project requirements and construction habits, GETO offers two main reinforcement systems:

Flat-Tie System

- No drilling required

- Cleaner vertical casting

- Fewer installation accessories

- Less workload for assembly teams

- Favoured in many housing and high-rise projects worldwide

Aluminium Formwork Flat-Tie System

Tie-Rod System

- Produces an extremely smooth forming effect

- Designed for projects with thicker walls or varying structural conditions

- Well-suited for building refurbishments and walls over 400 mm

Aluminium Formwork Tie-Rod System

This choice allows contractors to adopt a formwork solution that aligns with their team’s experience while still upgrading to a modern construction method.

Engineering Features That Stand Out

GETO places strong emphasis on standardisation. Panels are produced with high-strength aluminium alloy and processed with machining and welding techniques that maintain dimensional accuracy. This is a key factor behind the high reuse rate—typically around 200–300 cycles, depending on site conditions and handling.

The forming results are another area where developers see clear value. Concrete surfaces often achieve flatness and verticality within 5 mm, which supports true plaster-free finishing. For large residential developments, this directly cuts down the overall finishing workload and makes quality control easier.

Safety performance is also integrated into the system. Once the formwork is assembled, the frame provides stable bearing capacity and strong resistance to deformation. Many contractors find that the lighter panel weight helps reduce labour strain while keeping installation efficient.

How GETO Aluminium Formwork Fits Into Real Projects

One of the reasons GETO is chosen for large-scale developments is that it can cover almost all major structural components—walls, decks, beams, staircases, and columns—within the same system. This unified approach helps teams avoid material mismatches and maintain consistent forming quality across the entire structure.

The system is widely used in residential towers, villa clusters, commercial buildings, hotels, offices, and underground structures such as utility tunnels and metro station elements. Developers working with complex schedules often note that the faster floor-to-floor cycle and reduced rework help bring overall delivery dates under tighter control.

Aluminium Formwork For High-Rise Residential Building

Support Beyond the Hardware

For many clients, GETO’s service is as important as the product. The company provides drawing optimisation, formwork layout design, onsite technical support, and training for installation teams. This helps contractors adopt aluminium formwork more smoothly, especially in regions where teams are transitioning from timber or steel.

Conclusion

The shift toward aluminium formwork systems is driven by practical jobsite priorities: quicker cycle times, a cleaner casting effect, higher repeatability, and significantly lower finishing workloads. Developers appreciate how the system stabilizes construction schedules while reducing the overall cost of delivering modern buildings.

With aluminium formwork suppliers such as GETO providing refined system options, structural design support, and high-quality manufacturing, more contractors are choosing aluminium formwork as a reliable long-term solution for concrete structures.

If you need help selecting the right aluminium formwork system or want assistance planning your next project, GETO can provide full engineering and product support tailored to your building requirements. Contact us at geto_market@geto.com.cn to get started.