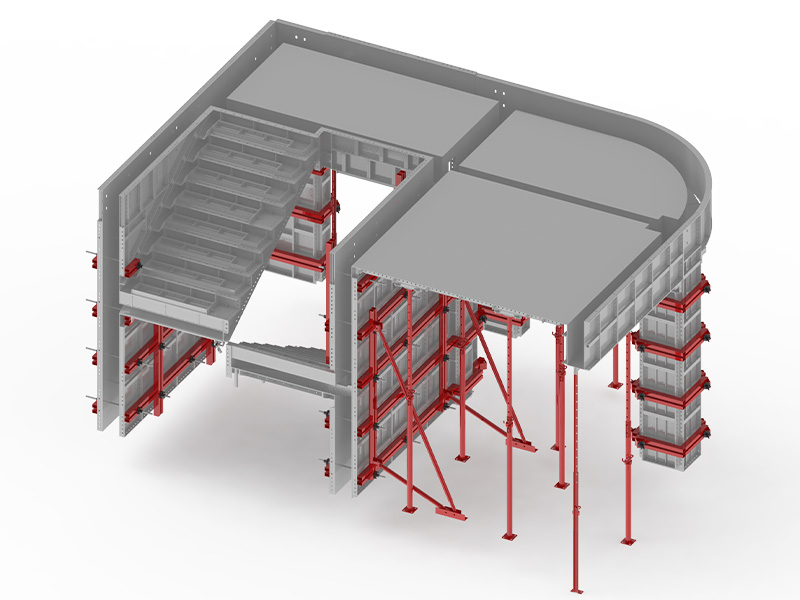

Formwork Systems

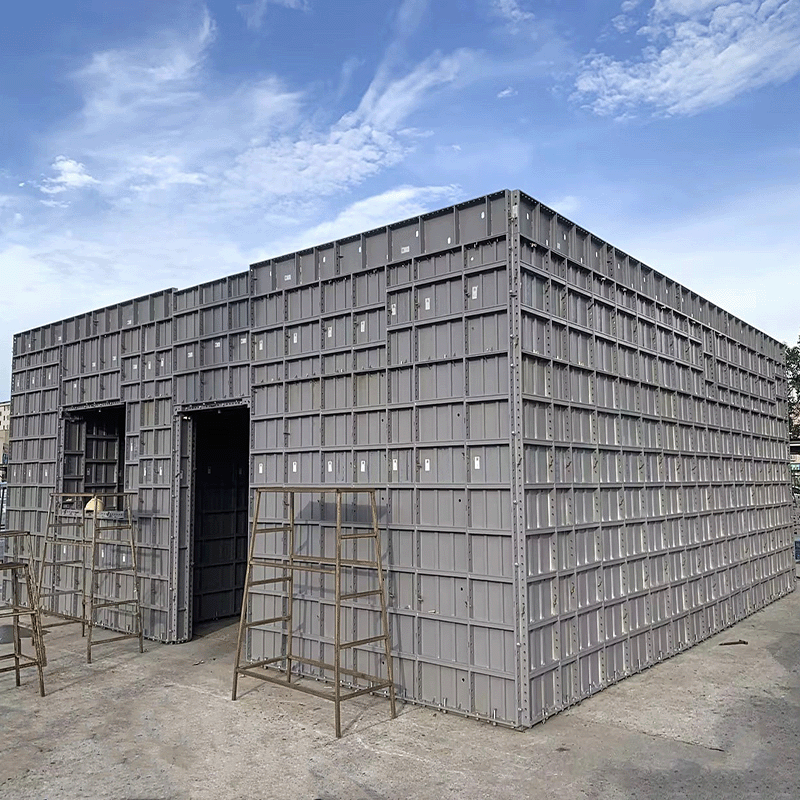

Flat-Tie System

The aluminium formwork with the flat tie reinforcement system is free of drilling, with the good vertical casting effectand fewer installation accessories, reducing the installation workload of workers, which is more in line with the use habits of workers in different countries.

Tie-Rod System

The forming effect of the tie-rod reinforcement system is very smooth. The tie-rod reinforcement system is more suitable for the refurbishment project with different structures and the project with wall thickness structures larger than 400mm.

Advantages

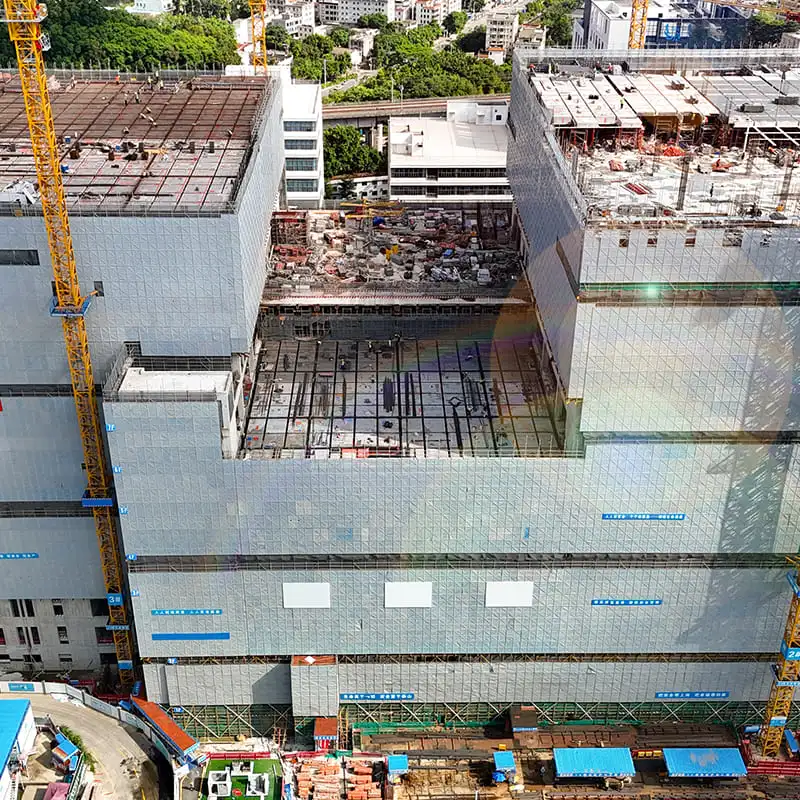

- High standardization in design: The aluminium formwork has a high rate of reuse, allowing for up to 200–300 reuse cycles, and is simple to install and disassemble.

- Excellent forming effect: Achieve verticality and flatness within 5 mm, reaching true plaster-free for both interior and exterior walls.

- High safety: The aluminum formwork material is characterized by its high strength, high bearing capacity, and resistance to deformation, forming a highly stable frame once the system is assembled.

- Less comprehensive cost: High utilization reduces integrated costs, lowers labor expenses due to quick assembly, minimizes heavy equipment leasing, cuts plastering and decoration costs, and benefits from high scrap value.

Specifcation

|

Item |

Specifcation |

|

|

Aluminium Alloy (6061-T6) |

Poisson's ratio (Va) |

0.3 |

|

Density (ρ) |

2.7g/cm³ |

|

|

Elasticity modulus (Ea) |

70000N/mm² |

|

|

Yield strength (Fa) |

200 N/mm² |

|

|

Shear strength (Fva) |

115N/mm² |

|

|

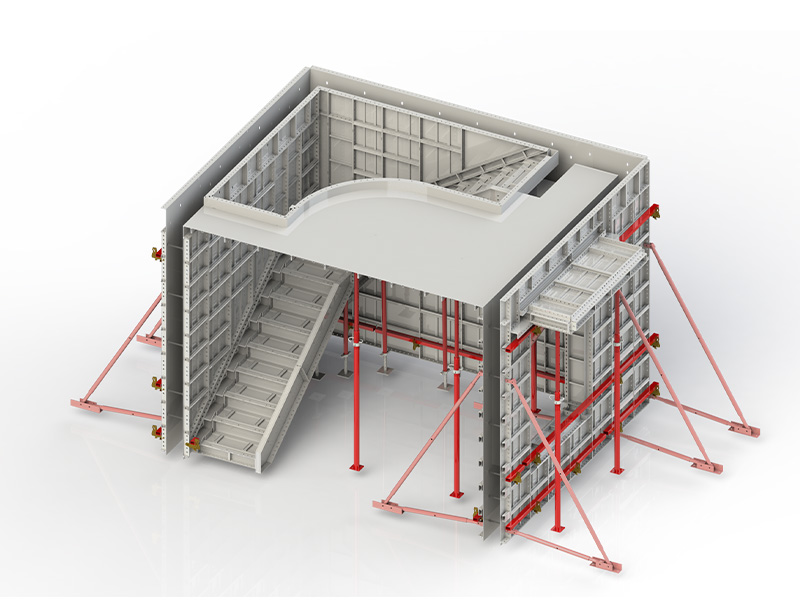

Composition |

Inner & Outer wall paneland corner panel |

|

|

Beam bottom & side panel and corner panel |

||

|

Slab panel & prop head and corner panel |

||

|

Staircase panel |

||

|

Alloy Temper |

6061-T6 |

|

|

Material Type |

Complete extrusion |

|

|

Main Welding Type |

Friction Stir Welding |

|

|

Thickness of Panel |

4mm |

|

|

Thickness of Frame |

8mm |

|

|

Height of Frame |

63.5 / 65mm |

|

|

Standard Wall Panel Width |

50mm to 600mm |

|

|

Standard Wall Panel Height |

2,400mm |

|

|

Standard Slab Panel Size |

600mm X 1,200mm |

|

|

Weight of Aluminium Panel |

25kg/sq.m |

|

|

Standard Prop |

Adjustable steel prop |

|

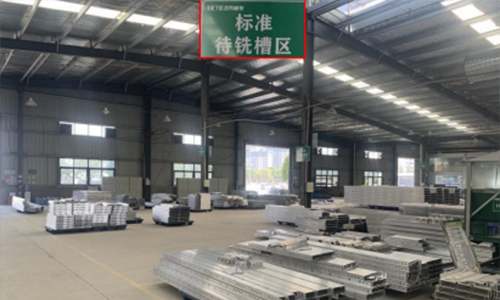

Production Process

1.Aluminum profile

2. Cutting

3. Punching & Drilling

4. Grooving

5. Welding

6. Full Inspection

7、Aluminium Formwork

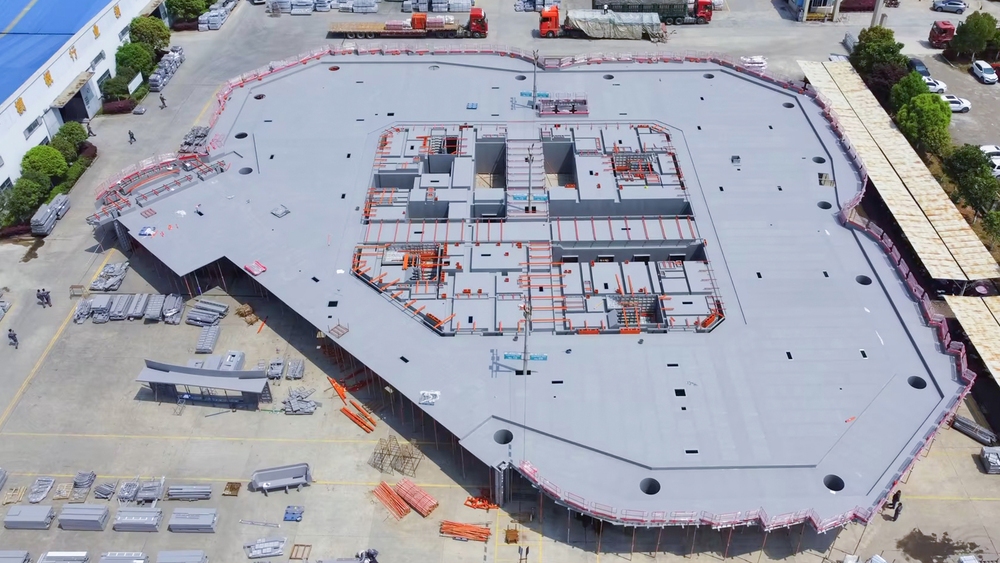

8. Trial-assembly (Optional)

FAQ

1.How many times the aluminium formwork is reused that it will cost less than timber formwork?

Aluminium formwork is used in buildings whose standard floors are more than 20 floors that the overall cost is lower.

2.What is the labor cost comparison between aluminium formwork and timber formwork?

Using aluminium formwork can save about 35% labor costs compared with timer formwork.

1.Does it need the experienced aluminium formwork installed workers?

Aluminium formwork is a standardized product and can be installed according to the drawings. Each panel has its own number that workers can find the related panel easily. It only needs a simple explanation for workers before installation.

2.Will the concrete pile up on the formwork after the formwork is used many times?

If the operation is carried out with construction standards, the demoulding agent is used with the provisions, and we will do a simple cleaning after each panel is used, this situation will not occur.

3.Does it need post-processing of the water and electricity pressure slots to use aluminum formwork?

No, we can make pressure slots on the formwork according to your water and electricity drawings to reduce the workload of secondary construction.

4.How do you deal with the stairs?

The staircase is also a whole moulding. In the pouring process, it can separate a few times to cast by opening a hole or opening part of the stair cover panels to make the higher quality staircase molding.

What are the supply steps and lead time of the self-climbing platform?

Normally, for 40 machine positions, it takes 10 days for deepening design, 35 days for production, 7 days for transportation, loading and clearance of goods, a total of about 52 days. The shipping time is determined according to different port’s and shipping company’s shipping schedules.

1.How about the effect of the concrete surface made with aluminium formwork?

After dismantling the aluminum formwork, it can achieve the effect of fair-faced concrete. The wall is smooth, the vertical flatness is 3mm-5mm, and there is no need for plaster.

2.Will there be aluminium formwork deformation or burst?

If you install with the construction standard, workers do not dismantle the formwork violently, there will not occur the situation of formwork deformation and burst. Before casting concrete, workers must check the reinforcement device.

1.What kind of project is suitable for using aluminum formwork?

Aluminum formwork is a new material to replace the traditional formwork. It is suitable for all kinds of ordinary houses, villas, high-rise office buildings and a series of modern buildings. As long as the standard floor is more than 20 floors, we recommend you to use aluminum formwork so that the overall cost is lower.

2.Can GETO aluminium formwork be used with timber formwork?

Yes, GETO can provide a full set of aluminium formwork systems, all structures of the whole project can use aluminium formwork. However, in some special parts, where the use of formwork is rare, we recommend using timber formwork. The combination of aluminium and wood can save your costs.

3.Can GETO aluminium formwork be used with prefabrication?

Yes, aluminium formwork can be combined with prefabrication. GETO would offer design plans according to the project.