Aluminium Shuttering is a popular choice in construction.

What is aluminium shuttering - 2025

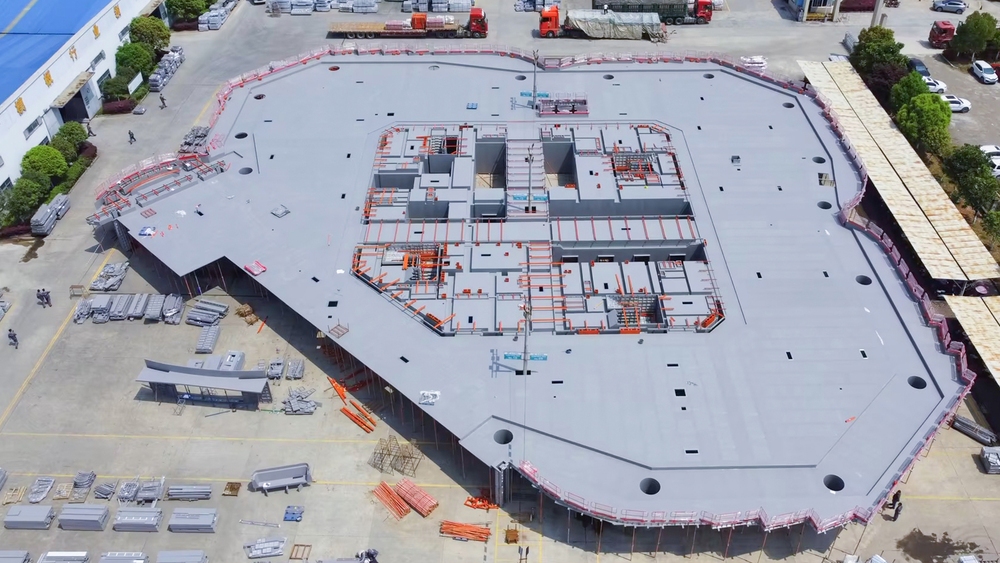

Aluminium shuttering is a new generation of construction formwork system after timber and steel formwork. Aluminium alloy profile is the main material, and it is made into formwork through machining, welding, and other processes. It is suitable for concrete engineering, super high-rise buildings, basements, residential buildings, utility tunnels, etc.

Aluminium Formwork can be assembled freely according to different structures and sizes. Its design and application are an innovation of formwork technology.

Formwork Construction & Aluminium Formwork Design

Types of GETO formwork system

As an experienced formwork system manufacturer, GETO has a very rich and complete formwork product system:

By material:

Timber Formwork

Steel Formwork

Plastic Formwork

Tunnel Formwork System

Steel-Framed Timber Formwork

By application scenario:

By function:

PPVC Precast Housing Molds

Quick-Deck System

Single-Side Wall Framework

Table Formwork

Aluminium Formwork For Basement

Shaft Steel Formwork System

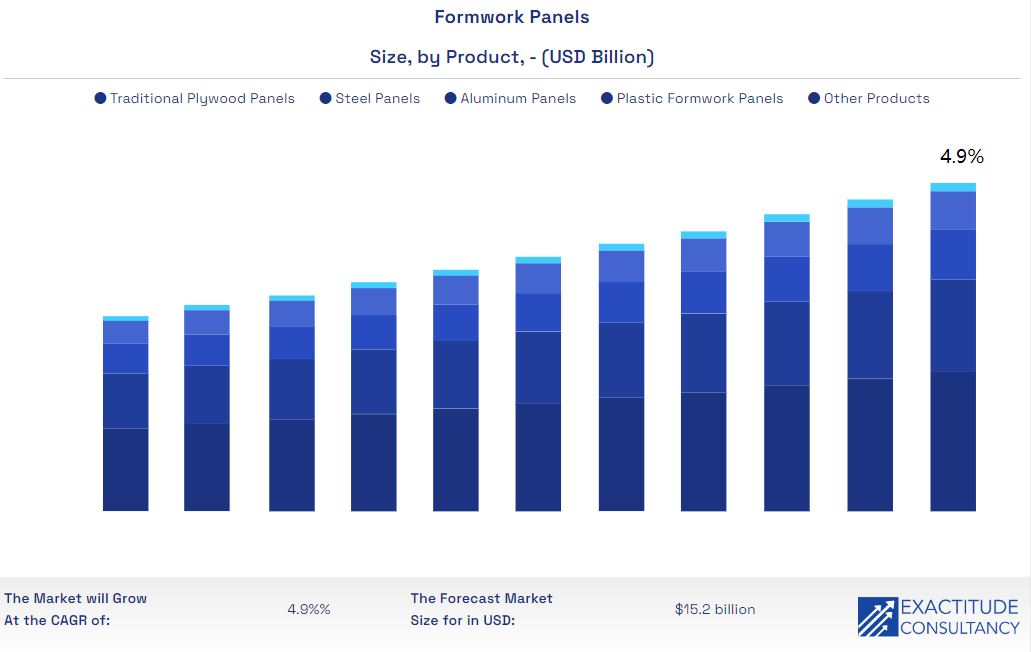

The global formwork panels market is valued at approximately $9.6 billion in 2024. And, the global market demand for efficient building solutions is growing.....

Advantages of aluminium shuttering

Excellent forming effect

Aluminium shuttering uses a large, single-piece formwork to minimise joints and ensure an even surface finish. Its high precision ensures accurate alignment and structural integrity. Its high load-bearing capacity means the system remains stable under the weight of wet concrete and, crucially, it produces a high-quality concrete surface that meets clear water standards, without the need for plastering.

Less construction cost

Compared with other formworks, aluminium formworks are more cost-effective. The reason is its high utilisation rate. The faster and more convenient installation process saves high labour costs, and it can also minimise the rental costs of heavy equipment such as cranes. In terms of surface treatment, it saves plastering and decoration costs. After the construction is completed, it can also be recycled.

Increase construction speed

Since the aluminium formwork system is lightweight, workers can carry and assemble it without any equipment. The assembly process is as simple and flexible as building blocks. Therefore, it can save construction time.

Aluminum is tougher and more solid after assembly

Aluminium is a material with high strength, strong bearing capacity, easy to handle and is not easy to deform. The overall frame formed after the system for forming is assembled is highly stable. During the assembly process, there is no need to call a crane or perform dangerous high-altitude operations, which greatly reduces the chance of falling accidents.

Aluminium shuttering can be recycled many times

The service life of aluminium formwork can reach an astonishing 200-300 times. Waste aluminium formwork can basically be recycled, which can reduce the generation of construction waste to a certain extent and be cost-effective.

Conventional formwork vs aluminium formwork.

|

Characteristics |

Steel Formwork |

Timber Formwork |

Aluminium Formwork |

|

Material Performance |

|||

|

Average weight |

35-85kg/m² |

10.5kg/m² |

25-27kg/m² |

|

Loading capacity |

30-60kN/m² |

30kN/m² |

60kN/m² |

|

Tensile strength |

≥370MPa |

≥120MPa |

≥260MPa |

|

Characteristics of Installation Process |

|||

|

Installation difficulty |

Low |

High |

Lowest |

|

Labour intensity |

High |

High |

Low |

|

Security risk |

High |

High |

Low |

|

Depend on lifting machinery or not |

Need |

Need |

Needless |

|

Concrete Forming Effect |

|||

|

Concrete surface quality |

Rough,clean |

Rough |

Glossy,smooth |

|

Need to plaster or not |

Needless |

Need |

Needless |

|

Precision |

High |

Low |

High |

|

Comparison of Cost |

|||

|

Amortization cost |

High |

High |

Low |

|

Scrap value |

Middle |

None |

None |

|

Environmental Protection |

|||

|

Environmentally friendly |

Yes |

No |

Yes |

|

Generate construction waste or not |

None |

Much |

None |

|

Common formwork |

30-40 times |

3-5 times |

150-300 times |

|

Efficiency |

|||

|

Efficiency |

8-10 days/Floor |

10-12 days/Floor |

4-6 days/Floor |

|

*The data above are from GETO's construction experience. |

|||

The difference between geto aluminum formwork and its peers

Geto aluminum formwork includes a tie-rod system

By using GETO's tie rod reinforcement system, the building's moulding effect will be smoother. It is suitable for renovation projects of different structures and structural projects with wall thickness greater than 400mm.

Tie-Rod System - Geto Global Technologies

And an efficient flat-tie system

The template with a flat tie system not only does not need drilling, but also has a better vertical pouring effect.

In particular, the simplification of installation accessories greatly reduces the installation workload and complexity of workers, which is more in line with the usage habits of overseas workers.

Aluminium Shuttering Material & Aluminium Formwork Accessories & Aluminium Formwork Components

Related articles:Aluminium Formwork System Overview: Types and Major Components

How Geto aluminium shuttering works? Let’s watch the construction process.

Geto offers global customization solutions for aluminium shuttering.

Combination of formwork systems - Skyscrapers use aluminium shuttering and self-climbing platforms

By providing an integrated design of the aluminium shuttering and the self-climbing platform system, we are able to provide an effective solution to improve the efficiency of the structural engineering progress of super-tall skyscrapers. In this case, GETO customised the design of multiple connection points between the aluminium shuttering and the self-climbing platform system, for example, we will provide additional reinforcement accessories and steel frame structures.

Aluminium Formwork Best Practices

Geto successful projects display.

Our cooperation scope covers six continents, namely Asia, Europe, North America, South America, Africa and Oceania, and more than 50 countries and regions, including 35 countries along the "Belt and Road", and has successfully completed more than 400 high-quality overseas projects!

Metal Formwork & Aluminium Formwork For Construction

Aluminium Formwork Column

Why Aluminium Formwork is Revolutionizing Modern Construction?: Cost, Efficiency, and Technology Explained.

In modern construction, aluminium shuttering construction is rapidly becoming the mainstream choice, especially for high-rise residential and commercial projects, thanks to its efficiency, precision, and reusability. Compared to traditional formwork systems, aluminium formwork shuttering utilizes lightweight, high-strength aluminum alloys, streamlining the construction process and significantly enhancing build quality and speed.

Selecting the right aluminium shuttering material is crucial to ensuring long-term performance. High-quality aluminum offers excellent corrosion resistance and reduced deformation, minimizing maintenance needs. On-site, following aluminium formwork best practices—such as modular design, BIM clash detection, and worker training—can greatly improve project efficiency and reduce construction errors.

As the market evolves, shuttering latest technologies are integrating smart features like RFID tracking and digital management systems, dramatically enhancing visibility and control across the project lifecycle. In terms of cost, while the cost of aluminium formwork may be higher initially compared to timber, its high reusability, shorter construction time, and reduced need for rework result in better overall cost-effectiveness.

When comparing steel formwork vs timber formwork, steel is durable and strong but heavy and labor-intensive, while timber is more flexible and affordable but less durable. Aluminium formwork offers a balanced solution—lightweight, durable, and highly reusable—making it a preferred choice for many contractors.

Industry leader Geto Construction exemplifies the integration of aluminium concrete shutters with modern project requirements. Their modular systems are widely applied in PPVC (Prefabricated Prefinished Volumetric Construction) projects, where precision and standardization are critical. Aluminum formwork is ideal for PPVC due to its dimensional stability and ease of assembly and disassembly.

In practical aluminium shuttering work, teams must adapt the formwork layout to suit various structural elements, ensuring smooth concrete pouring on-site. As for the question of “when to choose aluminium formwork,” the answer is clear—it’s the best choice when working with tight schedules, high quality standards, short construction cycles, and the need for repetitive use.

Ultimately, the evolution of aluminum formwork technology is driving the construction industry toward greater industrialization and sustainability. From boosting efficiency to supporting green building initiatives, aluminum formwork systems are quietly reshaping the future of global construction.