In the modern construction industry, floor slab construction is a crucial aspect. Especially in high-rise buildings, large commercial projects, and complex structures, improving construction efficiency, shortening construction time, and ensuring safety are challenges that construction companies and contractors must address. The GETO Quick Deck System, as a new type of rapid floor slab formwork system, has quickly become a popular choice in the market due to its unique design concept and construction advantages. This article will delve into the advantages, features, and applications of the GETO Quick Deck Formwork system in building construction.

What is the GETO Quick Deck System?

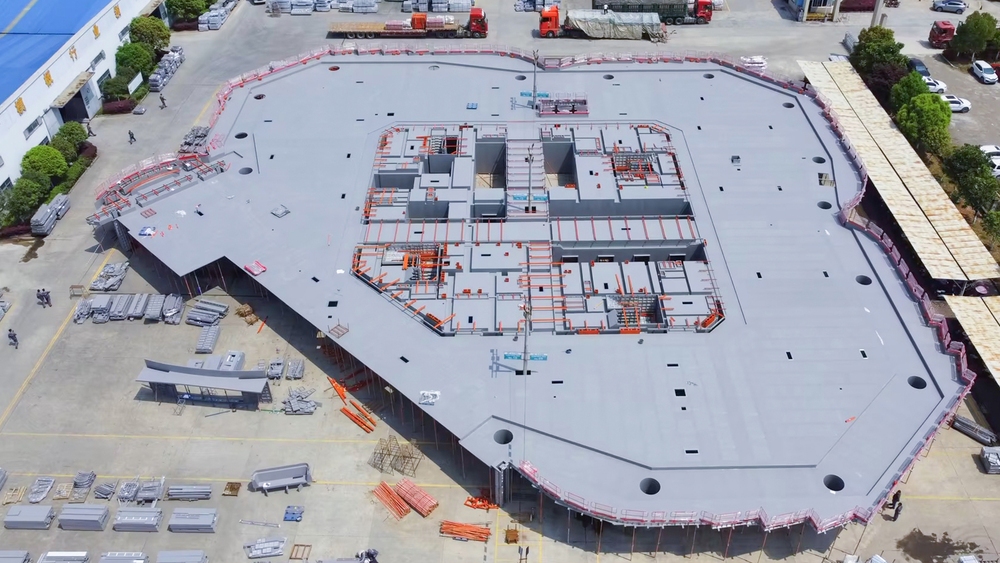

The GETO Quick Deck System is a highly efficient formwork system specifically designed for beam-free and large-area floor slab structures (such as garage roofs, building platforms, etc.). Its core feature is rapid installation and dismantling, achieved through the height adjustment of the adjustable supports below. During operation, construction personnel only need to manually raise the adjustable support head to fix the formwork in place, while dismantling is easily accomplished by simply lowering the support head.

This system's design makes the GETO Quick Deck System highly flexible and efficient on construction sites, suitable for most floor slab structures, especially in construction projects requiring large-area, beam-free structures. Its simple operation process and high compatibility have also made it the preferred choice for many construction companies.

Main Components and Functions of the Quick Deck Formwork System

1. Props System

The support system of the GETO Quick Deck Formwork system consists of specially designed supports and support heads. These supports can stably bear the weight of the formwork and securely fix the formwork in the appropriate position through the quick-release support heads. These support systems not only function during installation and dismantling but can also be adjusted in height as needed.

2. Deck Panels

The formwork panels are a key component of the GETO Quick Deck Formwork system. They are made of lightweight aluminum alloy, standardized in size, and moderately weighted (36.77 kg, 1.2m x 1.8m), making them easy to handle and install. Construction personnel can simply lift and fix the formwork panels onto the support system with a simple rotating motion. Furthermore, the formwork panels are designed to be transported using small handcarts, greatly improving the convenience of on-site construction.

3. Quick-release Prop Head

The quick-release prop head is one of the innovative designs of the GETO quick deck formwork system. It is not only compatible with traditional aluminum formwork systems but also allows for quick lowering of the formwork through a quick-release mechanism without affecting the stability of the support. This design not only improves dismantling efficiency but also ensures safety during the dismantling process, preventing accidental formwork drops.

4. Scaffolding System

In addition to the formwork and support system, the GETO quick deck formwork system can also be combined with other types of scaffolding systems. It is compatible with traditional aluminum alloy formwork systems, timber formwork systems, and precast concrete components, meeting the needs of different construction projects. Its modular design allows the system to be reused multiple times, reducing additional design costs.

Advantages of GETO Quick Deck System

GETO High Quality Quick Deck System

1. High Construction Efficiency

One of the core advantages of the GETO quick deck formwork system is the improvement in construction efficiency. Due to the lightweight and standardized size of the formwork panels, only a minimum of two workers are needed to complete the installation and dismantling of the formwork. This rapid operation process not only saves a significant amount of time but also effectively avoids the high mechanical costs associated with traditional formwork systems. In addition, these formwork panels can be transported via handcarts, which further enhances the efficiency of on-site operations

2. Easy Compatibility

The design of the GETO Quick Deck Formwork System makes it highly flexible and compatible with other formwork systems (such as timber formwork, aluminum formwork, precast concrete components, etc.). The standardized size of the formwork panels means they can be reused in different construction projects without requiring redesign for each project, reducing additional design costs.

3. Safe and Stable

The GETO quick deck formwork system uses a quick-release prop head and height-adjustable support devices to ensure that the formwork does not shift or fall during installation and dismantling. This design not only guarantees the safety of construction workers but also improves the stability of the formwork, reducing the occurrence of construction accidents.

4. High-Quality Concrete Surface

The GETO system, using aluminum alloy formwork panels, produces a far superior concrete surface compared to traditional formwork systems. The aluminum alloy material provides a smoother and flatter surface for the concrete, reducing the amount of work required for subsequent finishing.

5. Cost-Effective

Due to its reusable nature, the GETO Quick Deck System significantly reduces material costs. The lightweight formwork panels are easy to transport and install, reducing the labor intensity of construction workers and thus lowering labor costs. Simultaneously, the system's design compatibility makes it more adaptable, reducing unnecessary equipment investment.

Special Applications of GETO Quick Deck System

GETO Quick Deck System Application

The GETO Quick Deck System is suitable for beam-free and large-area slab structures, performing exceptionally well in projects such as parking garages and building platforms. Whether in high-rise residential buildings, commercial buildings, or complex large-scale infrastructure projects, the GETO system provides efficient, safe, and economical solutions for construction.

Furthermore, the GETO Quick Deck System can be perfectly integrated with existing aluminum formwork systems, timber formwork systems, and precast components, providing construction companies with flexible construction options. For example, the combination of the quick deck formwork and timber formwork systems can meet the specific needs of a project, ensuring project progress while guaranteeing quality.

Key Considerations When Choosing a Quick Deck System Supplier

When choosing a Quick Deck System supplier, construction companies and contractors should consider the following:

Formwork Quality and Technical Support

Ensure that the supplier provides reliable formwork quality and can provide technical support and training during the construction process to ensure construction safety and efficiency.

System Compatibility and Flexibility

Choose a supplier whose system is compatible with existing formwork systems, especially in situations with multiple projects and diverse needs, where flexibility is crucial.

After-Sales Service and Maintenance

High-quality after-sales service is essential for the long-term use of the formwork system. Choose a supplier that provides timely repair and maintenance services to ensure the system's long-term stable operation.

Conclusion

The GETO Quick Deck System, as an efficient, economical, and safe construction solution, has become an indispensable tool in modern construction projects. Through its advantages of rapid installation, dismantling, and reusability, the GETO system significantly improves construction efficiency, reduces construction costs, and enhances construction safety. For construction companies, choosing the right Quick Deck System supplier is crucial. As a leading scaffolding supplier in the industry, GETO can provide high-quality quick deck formwork systems for various construction projects worldwide, helping contractors stand out in the fierce market competition.