In the modern construction industry, innovations in construction technology are constantly driving improvements in efficiency, quality, and safety. GETO PPVC Molds (Precast Volumetric Construction) is a new type of construction technology that is leading the construction industry towards a more efficient, safe, and environmentally friendly future. This technology prefabricates entire rooms of a building as independent units in a modular fashion, which are then produced in a factory and quickly assembled on the construction site. This article will discuss in detail the working principles, advantages, and application areas of the GETO PPVC mold system.

What is PPVC Molds?

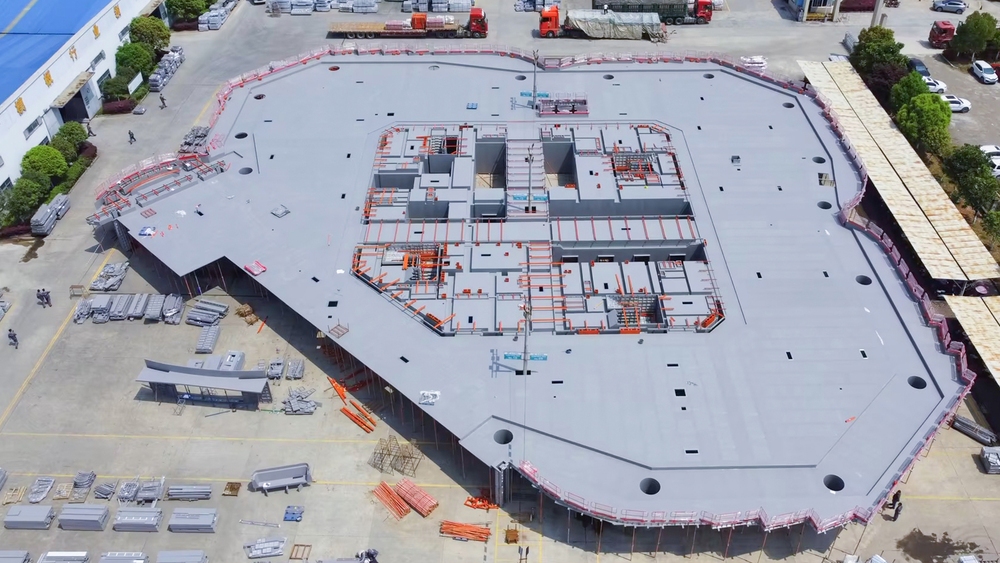

GETO prefabricated prefinished volumetric construction

PPVC (Precast Volumetric Construction) is a revolutionary construction method that completes the casting, prefabrication, and assembly process of entire rooms as modular units in a factory. The core of PPVC technology lies in its modular design, which allows building units (such as rooms, bathrooms, kitchens, etc.) to be cast and formed in their entirety in the factory. These modules are then transported to the construction site for rapid assembly, significantly shortening the construction cycle.

Applications of PPVC in Construction

The application of PPVC in construction has expanded widely to residential buildings, commercial buildings, infrastructure, and other fields. The PPVC system is not only suitable for residential buildings but also ideal for large-scale construction projects such as high-rise buildings, commercial centers, and medical facilities. Through this system, construction companies can achieve standardization, modularization, and intelligence in construction, thereby greatly improving construction efficiency and quality.

The advantages of PPVC are not only reflected in construction speed but also include reusable Molds, reduced waste of on-site construction materials, and lower labor costs. Especially in some demanding construction projects, the precision and quality control of PPVC make it a preferred choice for more and more construction companies.

How GETO PPVC Molds Work

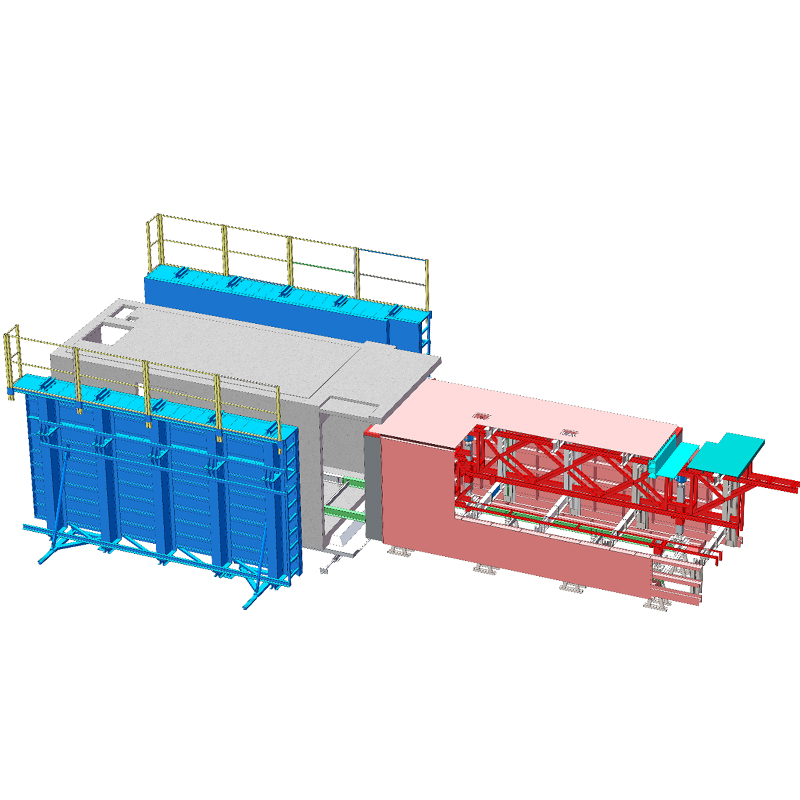

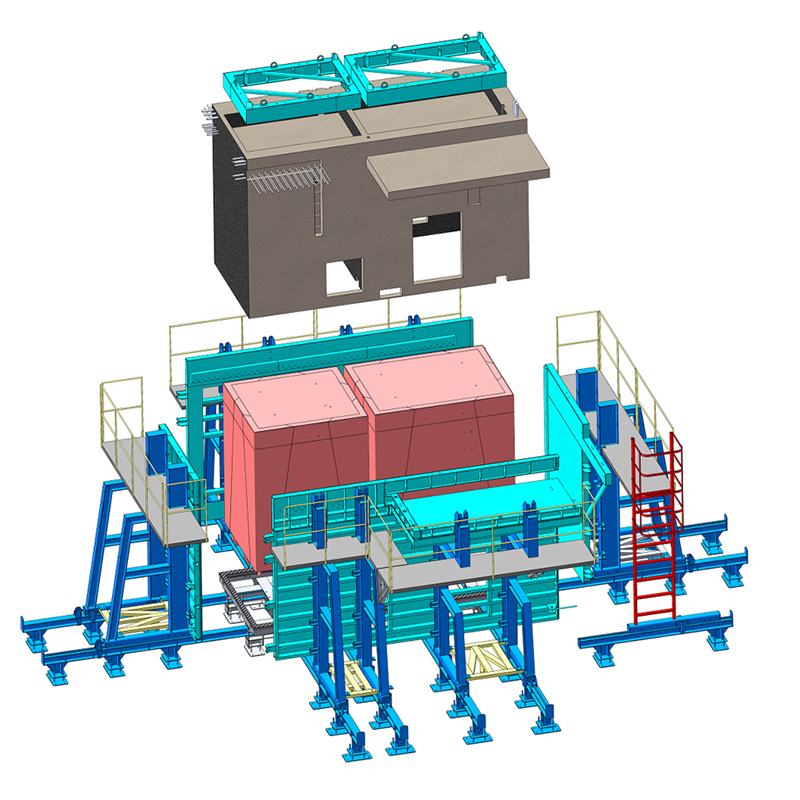

GETO's PPVC mold is based on the concept of modular construction, treating each room of the entire building (including walls, floors, doors, and windows) as an independent module. After production in the factory, these modules are transported to the construction site for rapid assembly and installation. This process includes the following key steps:

Precasting in Factory

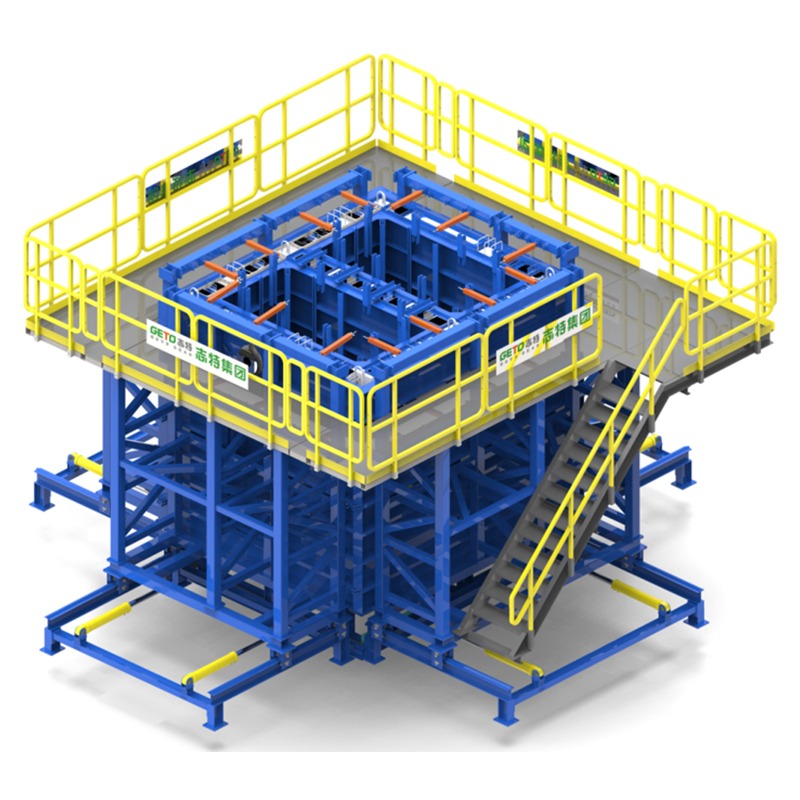

In the factory, GETO's PPVC precast housing mold system precasts each room as an independent unit. All structural parts (such as walls, floors, roofs, etc.) are cast in one go. High-strength Molds such as aluminum and steel formwork are used to ensure the strength and precision of each module.

Transportation & Installation

The precast modules are transported to the construction site and installed using simple mechanical devices. Due to the modular design, the installation process is not only fast but also precise, reducing potential errors during construction.

Casting & Forming

Once the modules arrive at the construction site, they are assembled to complete the casting of the overall structure. Unlike traditional casting processes, PPVC ensures construction accuracy and quality stability through precise factory production.

GETO PPVC Molds Series

GETO PPVC K Series

Semi-enclosed structure consisting of horizontal bottom and top slabs and three vertical walls.

GETO PPVC R Series

Semi-enclosed structure consisting of a horizontal top slab and four vertical walls forming an integrated module.

GETO PPVC H Series

Semi-enclosed structure consisting of four vertical walls forming an enclosed or semienclosed module body, without top or bottom slabs, and featuring cavity-free wall construction.

Main Advantages of GETO PPVC Molds

1. Efficient Construction, Time Saving

The GETO PPVC mold system significantly increases construction speed. Due to modular production, each room of the entire building can be completed in parallel in the factory, while the construction site only requires assembly and casting. This shortens the overall project duration by more than 50%. Compared to traditional steel formwork and concrete construction methods, PPVC technology significantly improves efficiency.

2. Reduced Labor Costs

The PPVC mold reduces reliance on manual labor through a highly automated production process. For example, the automated steel formwork system and adjustable support system can complete most of the assembly work in the factory, requiring only a small number of workers for assembly at the construction site, thus significantly reducing labor costs.

3. Better Quality Control and Safety

Because the PPVC mold system is manufactured in a factory environment, the production process is subject to strict quality control. While controlling quality, PPVC technology also reduces safety hazards during on-site construction, especially lowering the risk of workers working at heights.

4. Environmental Benefits & Sustainability

GETO's PPVC precast housing mold system aligns with the global trend of green building and low-carbon economy development. Because prefabrication takes place in the factory, it reduces waste generation at the construction site and improves material utilization efficiency. Furthermore, the reusability of the PPVC system makes it even more environmentally friendly.

5. Highly Adaptable

GETO's PPVC mold can flexibly adapt to different types of construction projects, such as prefabricated residential units, commercial buildings, and infrastructure, enabling efficient construction using this technology.

Applications Scenarios of Geto PPVC Molds

GETO PPVC mold are widely used in various fields, especially suitable for the following types of construction projects:

High-rise Residential Buildings

Suitable for large-scale high-rise residential construction, enabling rapid assembly and construction to meet the housing needs of modern cities.

Commercial Buildings

In the construction of commercial buildings, PPVC can provide efficient construction solutions to meet the high standards of commercial facilities.

Infrastructure Projects

For infrastructure projects such as precast concrete box culverts and precast concrete pipe galleries, using the PPVC system can effectively improve construction efficiency and reduce project costs.

Key Considerations When Choosing a GETO PPVC Molds Supplier

PPVC Precast Housing Molds Supplier - GETO

When choosing a GETO PPVC mold supplier, construction companies and developers need to consider the following key points:

Experience and Technical Support

Choose a supplier with rich experience and advanced technology to ensure the provision of high-quality PPVC Molds and professional technical support.

Product Quality and Innovation

Ensure that the PPVC precast housing Molds provided by the supplier meet building standards and have good innovation capabilities to meet the needs of different projects.

Project Cases and Reputation

Refer to the supplier's successful cases and customer reputation, and choose a brand with a good market reputation.

Conclusion

GETO's PPVC mold is an important technology for the future of the construction industry. It can significantly improve construction efficiency, reduce costs, and ensure construction quality, with broad application prospects. With the increasing demand for efficient, environmentally friendly, and intelligent building solutions in the construction industry, PPVC technology will undoubtedly become an important development direction in the construction field. Choosing an experienced and technologically advanced PPVC supplier like GETO will help construction companies achieve higher project efficiency and higher quality construction results.