Choosing the right shoring system is one of the most important steps in ensuring the safety, efficiency, and success of any construction project. Shoring systems provide temporary support for structures while concrete sets or heavy loads are installed, helping construction teams maintain stability and meet project deadlines.

GETO, a leading shoring system manufacturer and supplier in China, offers a wide range of solutions designed for various construction needs, from commercial buildings and bridges to tunnels and industrial facilities. This guide will walk you through the different types of shoring equipment and help you select the best option for your project.

What Is a Shoring System in Construction?

A shoring system in construction is a temporary support structure that holds up walls, beams, or floors during construction. Its purpose is to maintain the integrity of the structure until it can support itself. The right system not only enhances safety but also improves construction efficiency and reduces costs.

Shoring systems vary in material, design, and application. GETO offers multiple types to accommodate different load requirements, site conditions, project scales, and assembly efficiency, making it easier to find a shoring solution that fits both small-scale projects and large infrastructure developments.

Shoring Systems in Construction Project

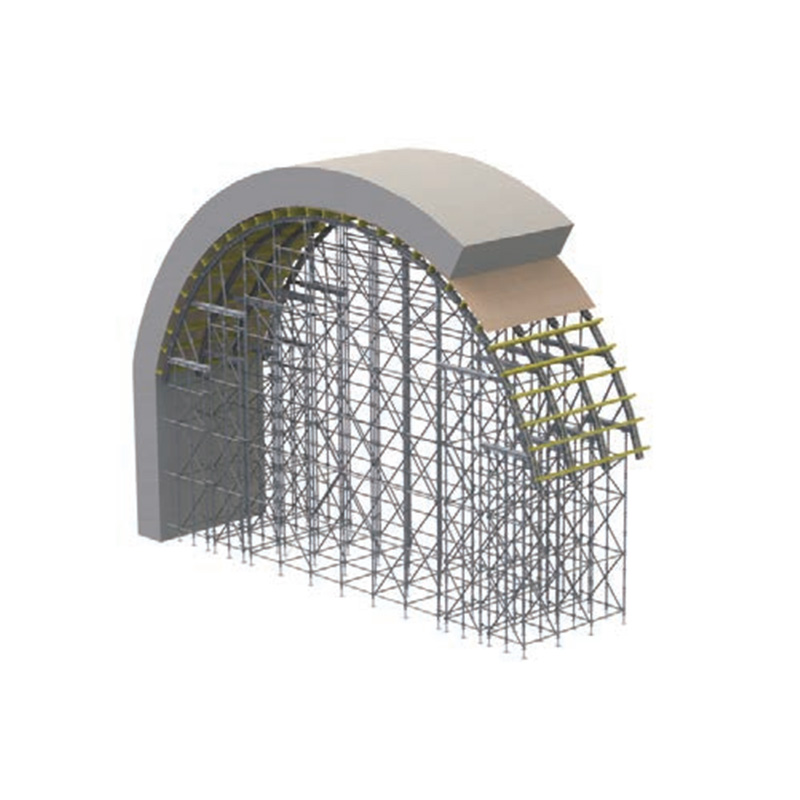

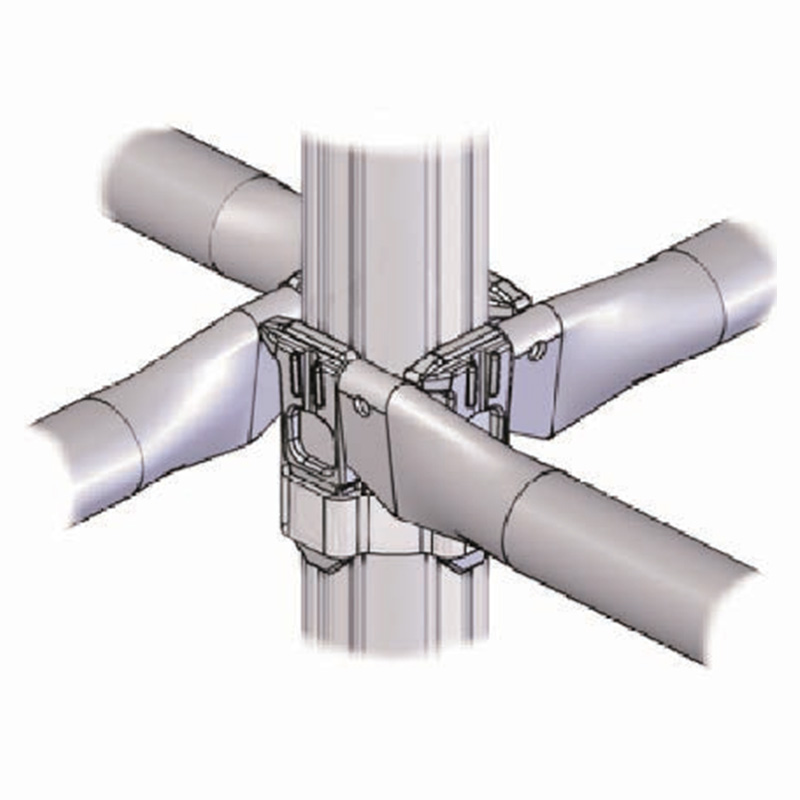

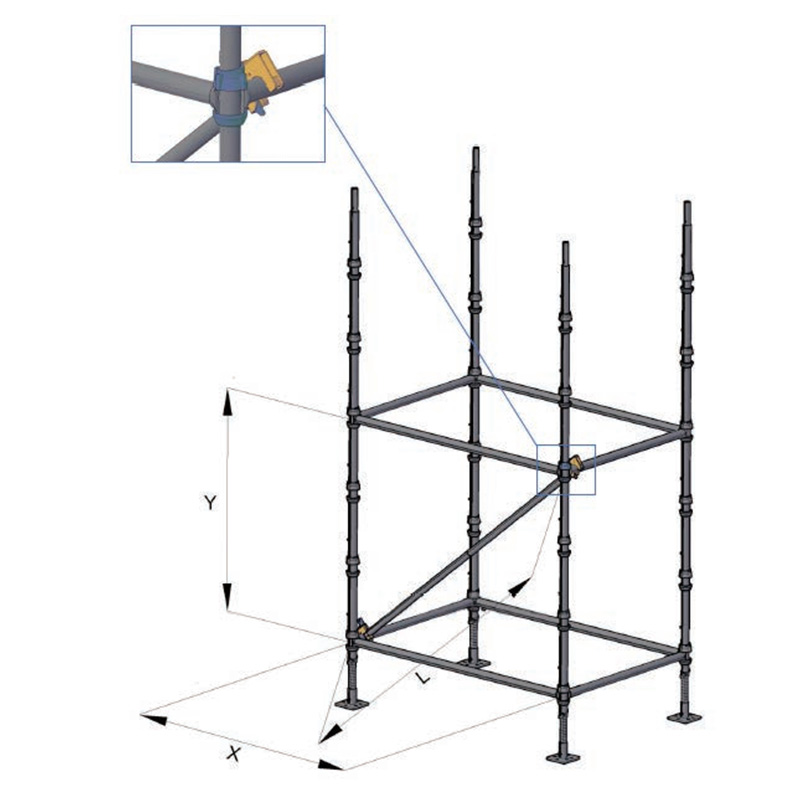

1. Ringlock Scaffolding System

The ringlock scaffolding system is versatile and widely used in bridge projects, tunnels, factory buildings, power plants, and elevated water towers. GETO offers M48 and M60 standards, with lengths ranging from 500mm to 3000mm, made from high-quality steel (0345 and 0235).

Advantages:

High Load Capacity: Single poles can support up to 19 tons in the 60 series.

Durable and Safe: Hot-dip galvanization ensures long service life and corrosion resistance.

Quick Assembly: Disc self-locking plug design improves construction efficiency.

Cost-Effective: Reduced steel consumption and lighter weight, lower transportation and labor costs.

Applications:

M48 Ringlock Scaffolding System: Civil construction and light-load projects.

M60 Ringlock Scaffolding System: Municipal engineering, rail transit beams, and large-span structures.

Ringlock scaffolding is an ideal choice when strong support and flexible spacing are required.

Ringlock Scaffolding System Supplier

2. H-Frame Scaffolding

H-frame scaffolding is widely used in building construction, bridges, tunnels, and halls. It is often employed as a primary support for table formwork.

Advantages:

- Suitable for both internal and external high-rise scaffolding.

- Composed of the main frame, transverse frame, cross brace, scaffold board, and adjustable base.

- Surface options: pre-galvanized, hot-dip galvanized, painted, or powder-coated.

H-frame scaffolding, widely used for structural frameworks, stair railings, and roof supports, offers a straightforward and reliable shoring system for construction projects requiring modular, high-strength support.

H-Frame Scaffolding Manufacturer

3. Tower Support

Tower supports are modular truss formwork supports capable of heights up to 25 meters. GETO tower supports are ideal for large-span industrial plants, airports, metro stations, box girders, shopping malls, and basements.

Advantages:

- Only five components, simplifying logistics and site management.

- Modular assembly allows fast installation and disassembly.

- Adjustable heights accommodate different construction needs.

- Cost-effective solution for large-scale projects.

Tower supports are perfect for projects requiring high elevation and strong load-bearing capabilities.

4. Steel Props

Steel props are essential temporary supports used for floorslabs during concrete casting. They provide adjustable height and strong vertical support, ensuring stability while the concrete sets. These are lightweight, easy to handle, and versatile across multiple construction applications.

5. Aluminium Beams

Aluminium beams are lightweight, durable, and highly resistant to corrosion, making them ideal for supporting building structures. They are commonly used with aluminium, conventional, or plastic formwork systems.

Advantages:

- Low weight yet high strength and load capacity.

- Corrosion-resistant, suitable for damp or chemically active environments.

- Easy to cut, drill, or weld on-site.

- Environmentally friendly and reusable.

Aluminium beams are particularly useful for projects that prioritize fast installation and mobility.

Aluminium Alloy I-Beam Supplier

6. Formwork Bracing Rib System

This system consists of aluminium beams and double U-steel beams, forming a robust top framework for various shoring setups. It allows wide spacing between supports while maintaining strength and stability.

Benefits of Aluminium Beams:

- High strength-to-weight ratio.

- Long design spans up to 2.4 meters.

- Adjustable on-site and easy to assemble.

Benefits of Double U-Steel Beams:

- Strong, lightweight steel with bolt connections.

- Pre-assembled for quick installation.

- Compatible with safety guardrails and other shoring components.

The formwork bracing rib system maximizes material efficiency while providing reliable support.

GETO Formwork Bracing Rib System

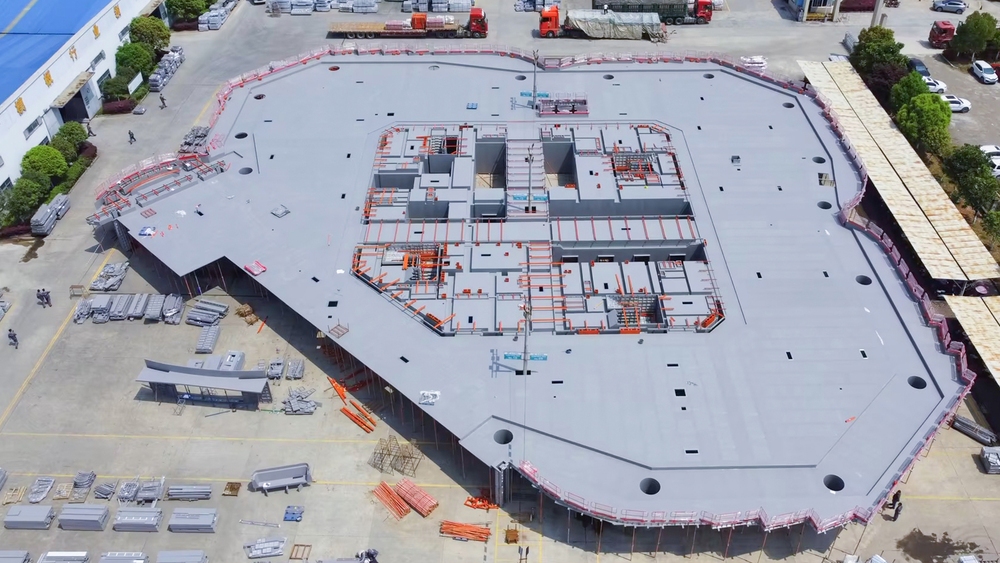

7. Modular Building Shoring System

GETO’s modular building shoring system is ideal for bridge construction and modular building projects. With telescopic rods on both the top and bottom props, it offers wide adjustment ranges and exceptional stability.

Advantages:

- Supports up to 190 kN per standard.

- Multiple ledger sizes for flexible support spacing.

- Hot-dip galvanized for long-term durability.

- Quick and secure assembly.

This system is particularly effective in projects with complex foundations or early stripping requirements.

Modular Building Shoring System

8. Duralok Shoring System

Duralok is designed for infrastructure projects like airports, railway stations, highways, metro depots, and water conservancy facilities.

Advantages:

- Forged nodes provide high rotational stiffness; single standards support up to 120 kN.

- Snap-on diagonal braces improve lateral stability.

- Hot-dip galvanization extends the lifespan of components.

- Multiple ledger sizes allow flexible layouts and faster assembly.

Duralok is ideal when site efficiency and material optimization are priorities.

Duralok Shoring System Manufacturer

9. Truss Shoring System

Truss shoring is used in heavy-load construction projects, including box girder casting, bridges, river crossings, and steel structure erection.

Key Benefits:

- Single standards support up to 450 kN.

- Flexible spacing for various ledger requirements.

- High overall stability and strength.

- Simple assembly with adjustable base jacks for uneven terrain.

Truss shoring is perfect for projects requiring maximum load support in challenging conditions.

10. Ringlock Shoring System (H2)

The ringlock shoring system combines ringlock scaffolding with a top formwork bracing rib system for wider spacing and stronger load distribution.

Advantages:

- Single standards support up to 150 kN.

- Durable, corrosion-resistant, hot-dip galvanized steel.

- Multiple ledger options allow flexible spacing.

- Fast and easy assembly with secure connections.

This system is well-suited for municipal and building engineering projects with varying load and span requirements.

Ringlock shoring System Factoty

How to Select the Right Shoring System

When selecting shoring equipment, consider the following factors:

- Load Capacity: Ensure the system can handle the intended weight safely.

- Height and Span: Tower or truss systems are better for tall or long-span structures.

- Site Conditions: Adjustable bases and modular designs help on uneven terrain.

- Assembly Speed: Faster assembly reduces labor and project costs.

- Durability: Look for corrosion-resistant materials for long-term use.

GETO provides a full range of shoring systems to match every project requirement. From lightweight aluminium beams to heavy-duty truss and ringlock systems, GETO ensures safety, flexibility, and efficiency for construction sites worldwide.

Conclusion

A carefully chosen shoring system improves safety, project speed, and cost efficiency. GETO offers innovative shoring solutions that cater to diverse construction challenges, including modular systems, tower supports, and heavy-duty scaffolding. Selecting the right shoring equipment ensures reliable temporary support, smooth project execution, and long-lasting structural integrity.

Explore the full catalog of GETO shoring systems and find the solution that meets the specific needs of your construction site. For further information, please feel free to contact us at geto_market@geto.com.cn.